Case Studies Real world data with predictive insights

We monitor mid-critical equipment across many diverse industries. See all of them and how AssetScan helped with their challenges.

Lubrication Fault on Industrial Fan

50-80% of root cause of failure of rotating equipment is due to poor lubrication practices. Watch how artificial intelligence is used to identify pre-existing lubrication defects on an industrial oven recirculation fan.

Hammermill Lubrication Study

Hammermills are designed to be destructive. A processing plant utilizing a hammermill is expecting to break down the incoming material into a smaller form for further processing. The breakdowns to avoid are in the mechanics of the mill.

Medical Waste Incinerator

A combustion air fan at a medical waste incinerator was upgraded to provide more air for the process. As a result of the alterations to the fan, and a 50 Hp larger motor, the fan bearings have prematurely failed since the fan was placed back in service.

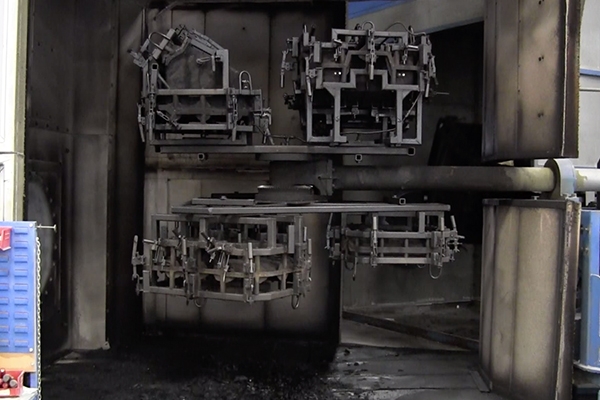

Foundry Predicts Fan Maintenance

The foundry did not have a vibration analyst and was following a preventative maintenance schedule for the pumps, motors, and fans. Plant maintenance, challenged to decrease unplanned maintenance costs, employed an AssetScan bearing fault monitor to perform an ad-hoc spot checks on critical equipment.

How Donaldson reduced maintenance costs and downtime

As a fuel filter traps contaminants, the pressure required to pump the fuel through the filter rises. Eventually the pressure will get high enough that flow is restricted and the pump can shut down, causing unscheduled downtime worth thousands of dollars.

Recycled Paper Plant

During a monthly route, the in-house vibration analyst finds a high vibration reading on a plant air compressor. Operations needs to run the process through the weekend and depends on the air supply. The compressor is placed on the ‘watch list’ but the vibration analyst does not work over the weekend.

Gas Fired Co-Generation Plant

The cooling water make-up pumps are located off site. While the plant maintenance staff has a vibration analyst, his duties allow only monthly route monitoring for the pumps. An unforeseen shaft failure on the primary pump left the plant at risk.

Iron Ore Processing

The 24-7 operation of the pelletizer furnace necessitates the constant operation of the cooling fans. The operating environment of the fans cause a buildup on the fan blades. Normal build up is consistent and the fan runs in a balanced condition. When the buildup gets thicker, chunks can break free and cause an unbalanced condition.

Wind Energy

The in-house maintenance tech performs routine maintenance routes. The equipment is under a maintenance contract where day-to day maintenance is on contract, large failures are paid by client.

Vertical Condensate Pump

The in-house operator performs routine maintenance routes, however equipment continues to break in the plant. In this case the pump shaft broke which resulted in a $125k repair event. The dominant failure mode of this pump is breaking the pump shaft.

West Air Makeup Unit

One of two air makeup units at a large Midwest casting manufacturer had failed before AssetScan had been deployed. Both air makeup units were the same vintage and unit two was suspected to fail. The AssetScan Bearing Fault Monitor was utilized on the second unit and excessive (g) forces were noted immediately.

Recycle Paper Plant Solution

Biweekly route monitoring identified a high vibration signal from a 1200 HP vacuum pump motor bearing. The plant operations group wants to be able to run until the next planned outage. Maintenance places the motor on the watch list and installs a battery powered ITT Gould Bluetooth vibration monitor.