Analytics Analytics to Action

AssetScan was built with the vision that analytics must be utilized in daily work in order to drive adoption and action from the insights generated. This is known as prescriptive analytics, or the recommended action to be taken from the data being collected and analyzed.

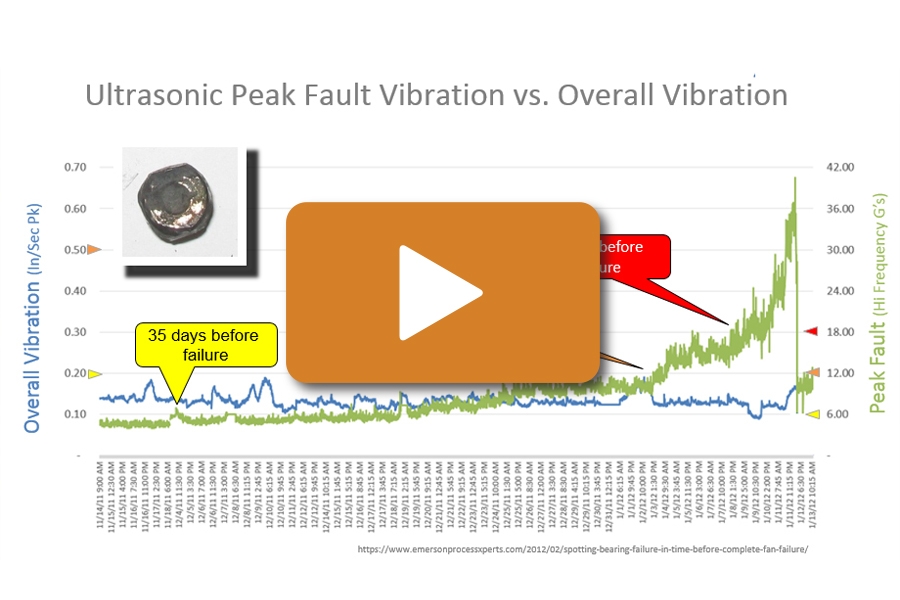

This value is underlined with robust edge computing that surrounds the Bearing Fault Detection or analysis of 100,000 data points per second, computed at the edge, rolled up and published at intervals you require to provide the real mean values that drive trend lines.

Predictive Intelligence

Predictive and prescriptive intelligence requires deep subject matter and Industrial IoT domain expertise to drive meaningful data, integration with existing systems and action. AssetScan was built to provide insight 30, 60 or 90 days in advance of failures, allowing for maintenance intervals or scheduled downtime to be accommodated well in advance.

Vibration 101

Vibration is an incredibly meaningful to understand the health of your rotating equipment, such as pumps, fans and motors. This value is underlined with robust edge computing that surrounds the Bearing Fault Detection or analysis of 100,000 data points per second, rolled up and published at intervals you require to provide the real mean values that drive trend lines. The need to distinguish Overall Vibration from Peak Acceleration is explained here.

Integration

Understanding what and how to integrate predictive maintenance solutions into existing workflows and systems is crucial to utilizing new prescriptive insights that drive results or reduce unplanned downtime. AssetScan continues to be a market leader by integrating into CMMS systems such as to push data and insight to action, or into workflows such as work orders for maintenance technicians.