Videos

Animation: AssetScan and OEM

ATEK has worked with OEMs for decades and provides part or entire solutions for OEM customers.

Case Study: 60-day Case Study on Non-OEM Repair of Fan

Ultrasonic monitoring was utilized to sense systemic issues and drove an improved lubrication program.

Case Study: Donaldson Case Study

Donaldson, a major OEM in filtration, utilized ATEK's technology expertise to embed in their proprietary product.

Case Study: Plastics Rotomolding Plant - Predictive Maintenance Case Study

Watch how a predictive maintenance program was initiated with AssetScan at a plastics factory.

IBM Sound Bytes: IBM AI in Cloud Migration and IoT

ATEK's Dan Yarmoluk and Craig Truempi discuss artificial intelligence in cloud migration and IoT in IBM Quick Bytes Live.

IBM Sound Bytes: IBM Maximo and Rest API

ATEK's Dan Yarmoluk and Craig Truempi discuss IBM Maximo and Rest API in IBM Quick Bytes Live.

Presentation: Predictive Maintenance & Real IoT Analytics & Data Usages

Craig Truempi, Director of IIoT Reliability discusses using analytics for predictive maintenance.

Software Demonstration: ATEK Intelligence Platform - AssetScan Software Demo

AIP (ATEK Intelligence Platform) is easy-to-use and customize. See how you can see single assets, trend lines or overall plant asset health across the organization globally.

Software Demonstration: CMMS Work Order Integration - Maximo

Learn how AssetScan Artificial Intelligence (AI) integrates with Maximo. Automate your CMMS Work Orders.

Software Demonstration: Remotely Monitor Oil Quality - AssetScan using Des-Case Sensor

50-80% of Root Cause of Failure of rotating equipment is due to lubrication. AssetScan can monitor your lubricant for moisture and particulate contamination and alert you at the onset of a problem before equipment damage occurs.

Video White Paper: Artificial Intelligence - Ultrasonic Alerts

AssetScan leverages artificial intelligence and ultrasonic alerts, namely, machine learning classifiers to drive and integrate into workflow.

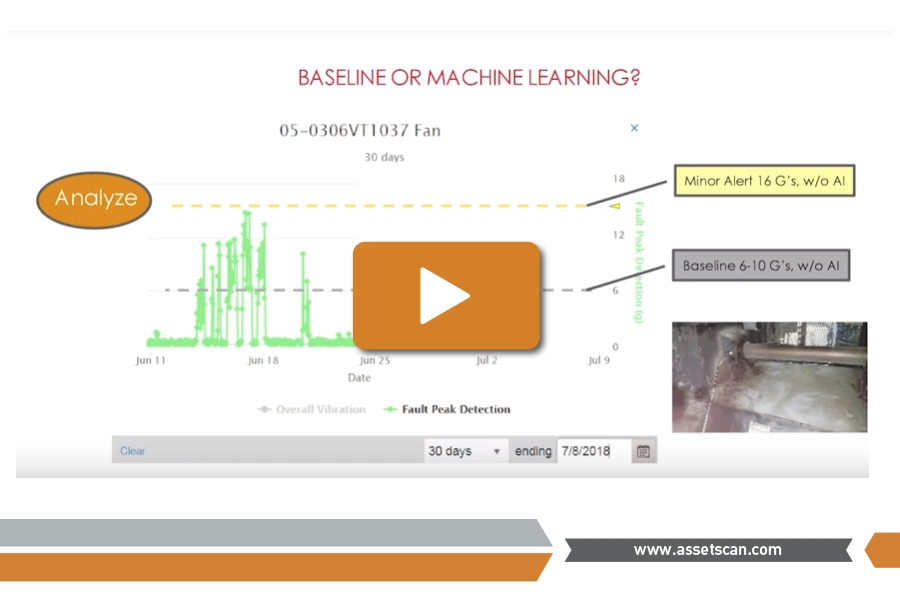

Video White Paper: Setting Vibration Alerts Without a Baseline

AssetScan's subject matter expertise in rotating equipment, vibration and reliability allows setting alerting functionality without the need to baseline.

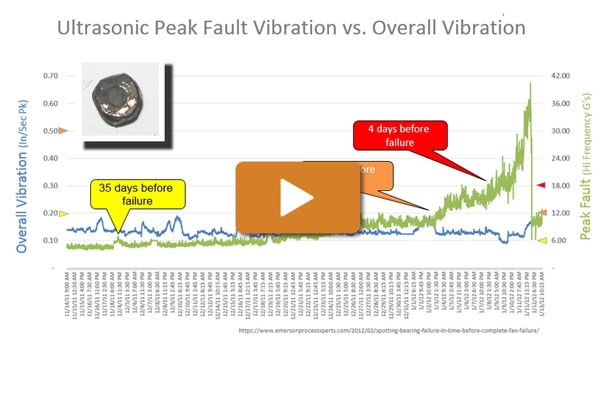

Video White Paper: Two Parts of Vibration - Overall & Ultrasonic

Overall vibration provides clarity on late-stage problems such as misalignment, looseness, but not predictive. See how ultrasonic vibration spots issues up to 90 days in advance with 1,000 - 200,000Hz of the wavelength spectrum.