Medical Waste Incinerator

The Challenge

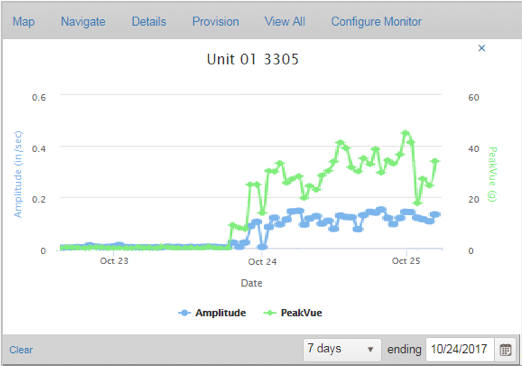

A combustion air fan at a medical waste incinerator was upgraded to provide more air for the process. As a result of the alterations to the fan, and a 50 Hp larger motor, the fan bearings have prematurely failed since the fan was placed back in service. A vibration analyst performing monthly route monitoring felt that more frequent monitoring data would help in determining the cause of the frequent bearing failures.

The Results

An AssetScan Bearing Fault Monitor was deployed on the suspect bearing and monitored the operation for a couple of months, collecting data over a series of operating conditions.The AssetScan monitor confirmed the fault conditions found at the inboard fan bearing. Subsequent maintenance practice improvements resulted in the bearing running much smoother from mid-December. The AssetScan monitor not only provided data to confirm the fault condition, the data showed the changes during the improved maintenance process, and then confirmed the smooth-running bearing.