Recycled Paper Plant

The Challenge

During a monthly route, the in-house vibration analyst finds a high vibration reading on a plant air compressor. Operations needs to run the process through the weekend and depends on the air supply. The compressor is placed on the ‘watch list’ but the vibration analyst does not work over the weekend. The analyst employed an AssetScan bearing fault monitor to watch the bearing fault with the ability to send an alert if a high level is reached at any time over the weekend.

The Results

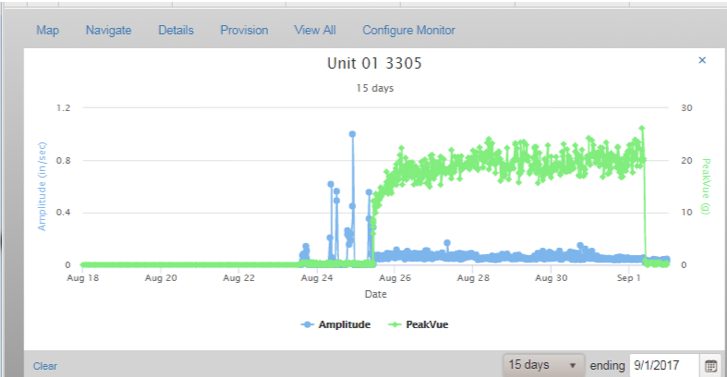

The compressor ran during the weekend, but as the data shows, the bearing fault condition continued to degrade. The ability to watch the condition and alert the operators and analyst if the bearing condition became critical gave the plant the confidence to continue to run through the weekend without needed the vibration analyst on site.