Gas Fired Co-Generation Plant

The Challenge

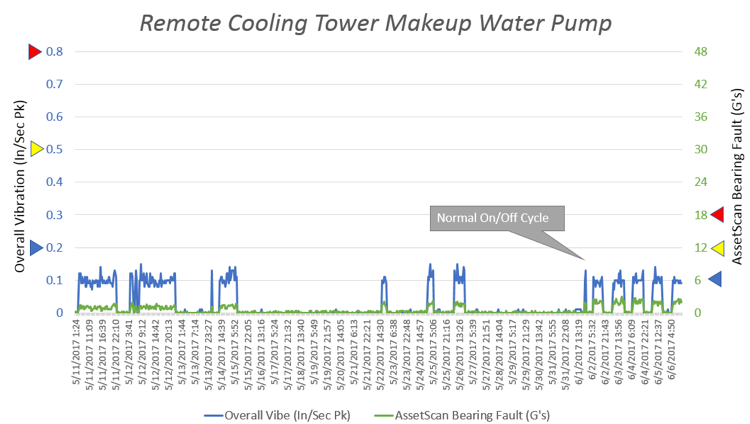

The cooling water make-up pumps are located off site. While the plant maintenance staff has a vibration analyst, his duties allow only monthly route monitoring for the pumps. An unforeseen shaft failure on the primary pump left the plant at risk. An AssetScan vibration monitor was deployed to monitor the secondary pump while the failed pump was repaired.

The Results

The power plant confidently ran during the repair period with the AssetScan monitor reporting the vibration levels on an hourly basis.The ability to send alerts to operations and maintenance if a high level is detected was paramount to creating that confidence. The historical record of the monitoring data was useful to create a better understanding of the pump cycles and run time.