West Air Makeup Unit

The Challenge

One of two air makeup units at a large Midwest casting manufacturer had failed before AssetScan had been deployed. Both air makeup units were the same vintage and unit two was suspected to fail. The AssetScan Bearing Fault Monitor was utilized on the second unit and excessive (g) forces were noted immediately. The unit was shut down and opened for an inspection and a significant gap between the bearing and the shaft was noted. A local contractor was consulted and confirmed the damage, and it was then decided to relocate the bearing instead of removing the shaft.

A split pillow block bearing was ordered and installed with a new support plate for the base of the pillow block. The following two pictures show the installation

The Results

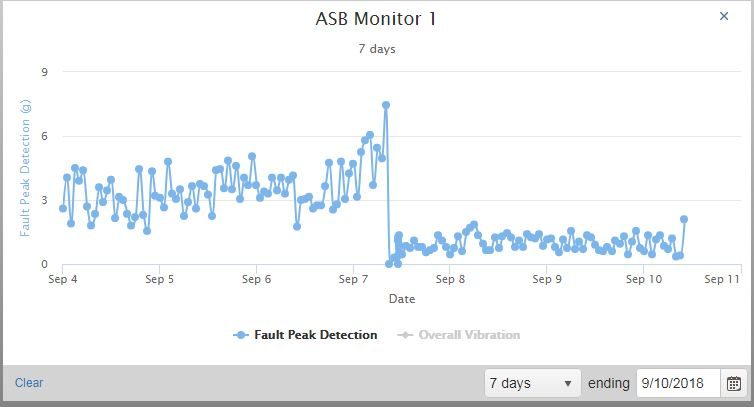

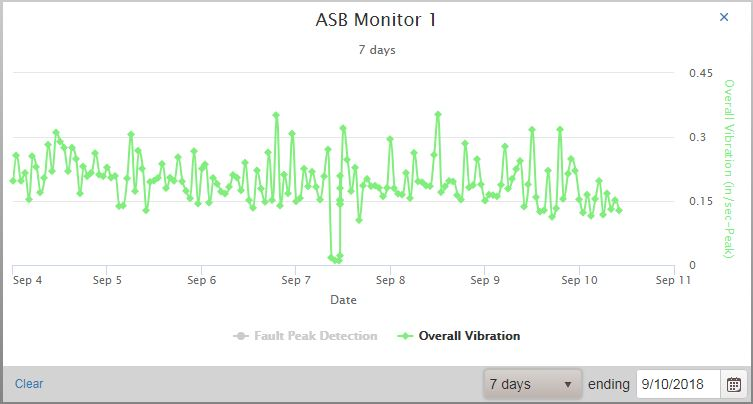

An AssetScan Bearing Fault Monitor was deployed on the suspect bearing and continuously monitored the operation for a couple of months, collecting data over a series of operating conditions. The AssetScan monitor confirmed the fault conditions found at the inboard fan bearing. Subsequent maintenance practice improvements resulted in the bearing running much smoother. The AssetScan ASB Monitor not only provided data to confirm the fault condition, the data showed the changes during the improved maintenance process, and then confirmed the smooth-running bearing.

The graph below shows the changes in both fault peak, and overall vibration levels. The fault peak measurements (g) have been reduced to more acceptable operating levels.