Recycle Paper Plant Solution

The Challenge

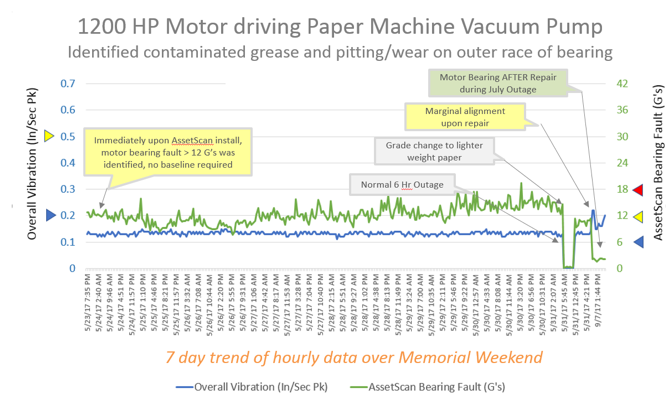

Biweekly route monitoring identified a high vibration signal from a 1200 HP vacuum pump motor bearing. The plant operations group wants to be able to run until the next planned outage. Maintenance places the motor on the watch list and installs a battery powered ITT Gould Bluetooth vibration monitor. The monitor does not alert out, nor when checked, is it indicating a fault condition. An AssetScan ASB bearing fault monitor is installed on the suspect bearing and immediately indicates a warning level fault condition. The ASB is left on the bearing and it monitors the progression of the fault condition until the outage. As the outage approached, the fault condition progressed to a critical level where replacement is recommended.

The Results

During the normal outage, the motor bearing was planned for replacement, avoiding unplanned shutdown of the paper machine. Subsequent monitoring of the ASB monitor showed a high overall vibration signal which was later diagnosed as a minor out-of-alignment condition.