Hammermill Lubrication Study

The Challenge

Hammermills are designed to be destructive. A processing plant utilizing a hammermill is expecting to break down the incoming material into a smaller form for further processing. The breakdowns to avoid are in the mechanics of the mill. Bearings are essential to the smooth running of the hammermill, but due to the constant jarring and impacting of the process, bearing failure was an all too common occurrence. Plant maintenance wanted to understand the root cause, and gather data to track the behavior of the bearings.

The Results

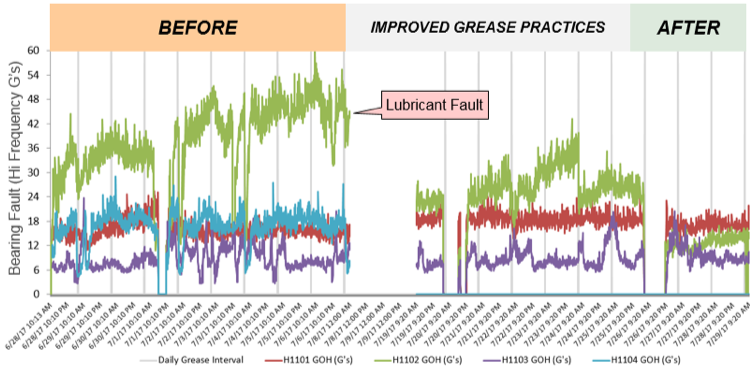

The AssetScan solution was deployed to collect before, during and after data while employing an improved grease practice. The ‘before’ data indicated high ultrasonic vibration levels were present in bearing 102. Improved greasing practices were employed over the course of a week with the ‘after’ data showing the resulting vibration levels decreased to acceptable levels.