Solutions Let your equipment tell you when it needs maintenance

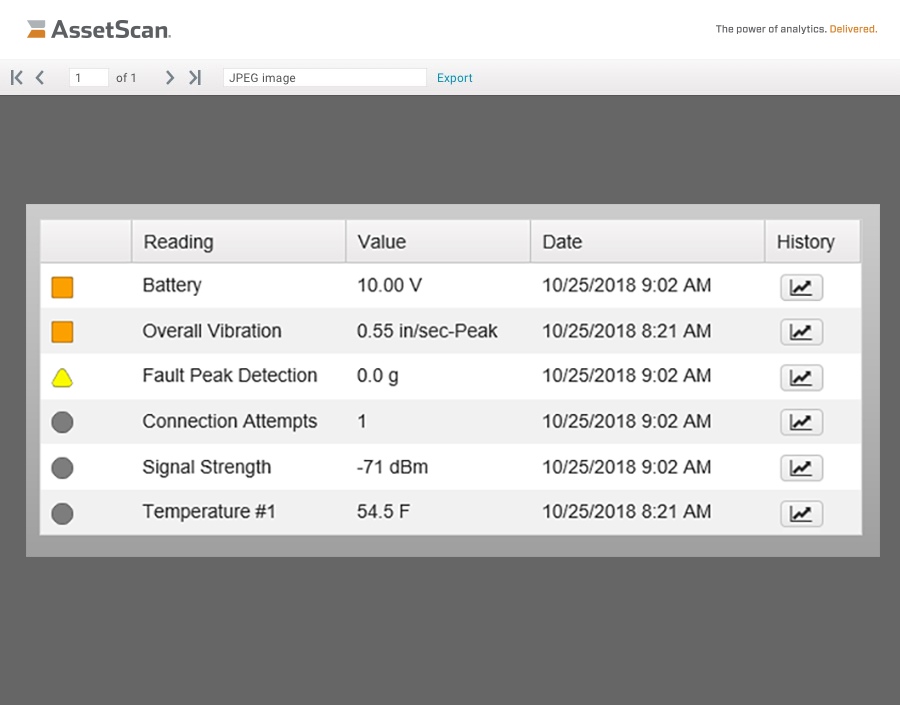

When one mechanical failure could jeopardize plant operations or result in unforeseen costs, you can’t take chances. But how can you be 100% sure your critical equipment is properly maintained and operating? AssetScan is a condition monitoring solution providing continuous vibration data and prescriptive work orders to enable complete visibility into your equipment and take the right action.

Root Cause with Data

AssetScan's "Crash Cart" application allows for short term yet continuous vibration and ultrasonic monitoring. While other technologies of the past take snap shot data, AssetScan automates the process of taking continuous trend data that is easier to follow and take action.

Acceptance Testing

AssetScan provides verifiable acceptance testing with a pass/no pass result on new or rebuilt rotating equipment. Beyond a visual or vibration spot check, AssetScan can be deployed for a 24-hour or longer period to verify the operating condition of the machine, as well as, the installation, over various load conditions that occur in typical plant operation.

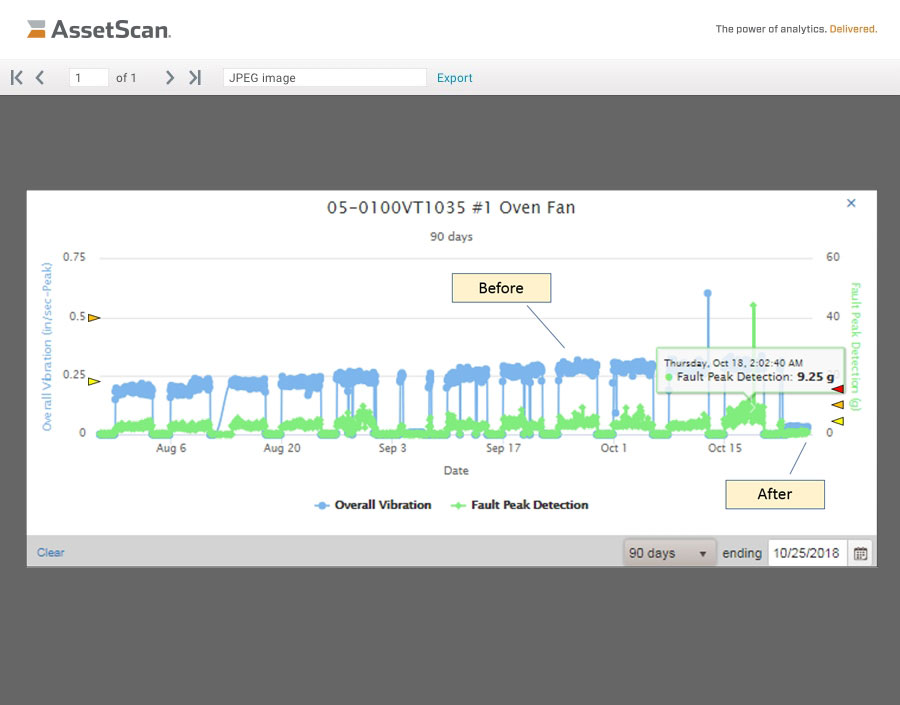

Death Watch

AssetScan's Death Watch is utilized by vibration analysts that have identified a suspect asset, yet it is too early to write a work order, or too high of a production loss to perform the repair. In this case, the machine is typically placed on a “watch list” where the analyst has insight to the operation of the asset while away, left on the suspect machine to monitor and alert out of a degrading situation.

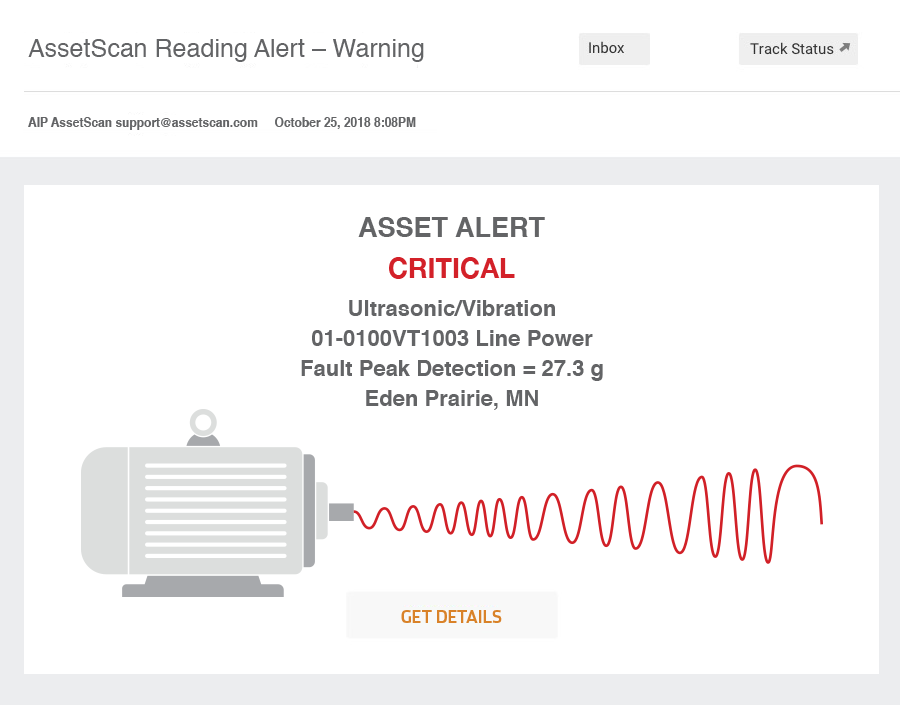

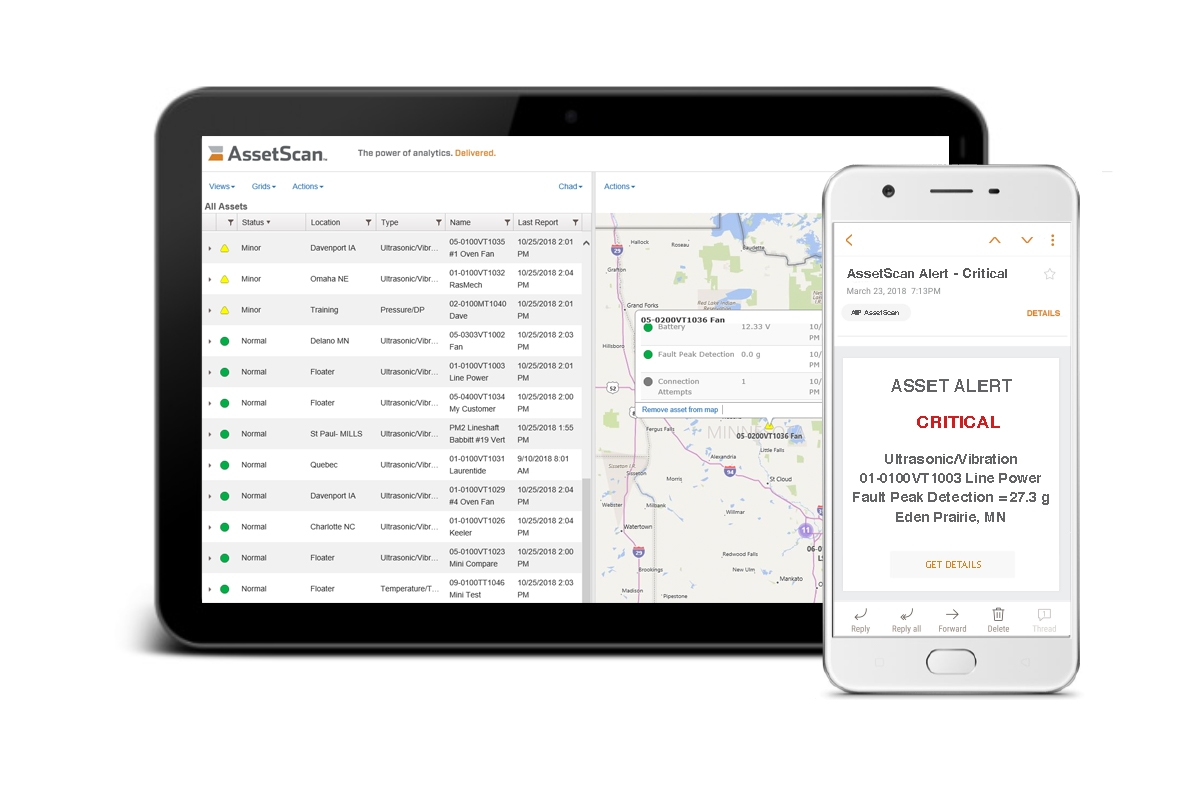

Remote Monitoring

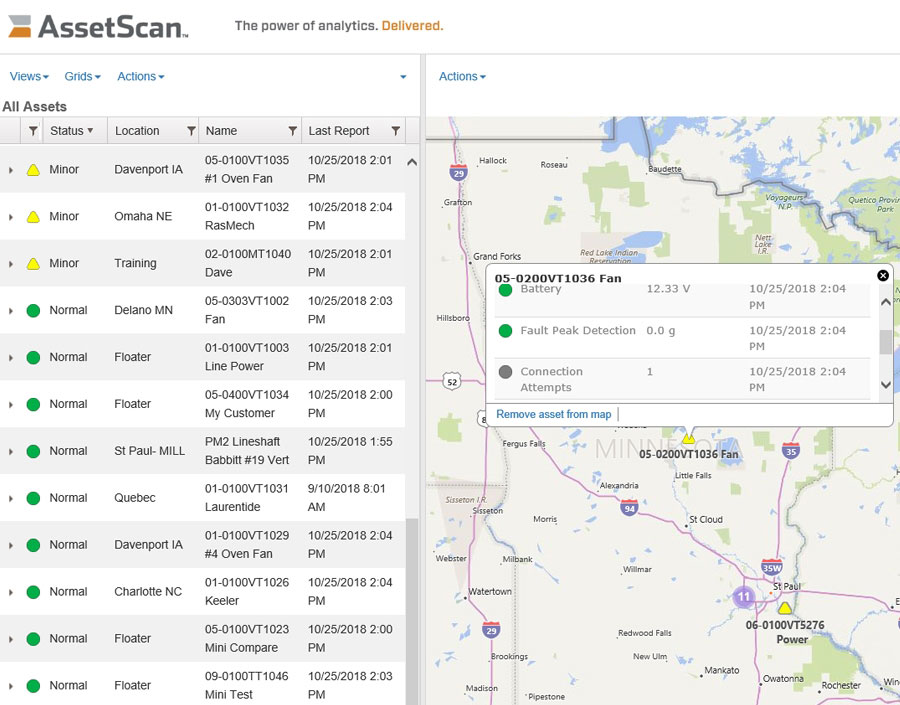

AssetScan's cellular and battery technology allow distant and dangerous asset data to be viewed via our AIP cloud intelligence platform by plant personnel from remote locations, anywhere they have access to an internet connection from their phone, desktop or laptop.

Continuous Condition Monitoring

When the criticality of the machine warrants continuous monitoring, AssetScan is fixed to the machine. Often with more critical machines it is desired to have more frequent update rates, which can be scaled up or down according to production needs.

OEM - Custom Design

Utilize AssetScan expertise in reliability and condition monitoring by incorporating our technology and analytics directly into your OEM products. AssetScan’s sensor agnostic design allows for any variable to be measured or utilize our proprietary ultrasonic vibration designs.

Technology

Condition monitor hardware and AIP Intelligence platform for predictive insights.

Simple To Install & Scale

Rapidly and easily deploy one to thousands of wireless monitors and optimize your operations.

World-Class Customer Care

Our team of experts has the market and technical knowledge to quickly get you up and running.